Fire Hydrant

Fire Hydrant: The Ultimate Guide to Fire Safety and Protection

Fire hydrant systems provide instant access to high-pressure water during emergencies. Learn how fire hydrants work, their components, and why they save lives.

Introduction: Why Fire Hydrants Are Life-Saving Infrastructure

🔥 Did you know that in a large fire, flames can double in size every 30 seconds? In that short span, a delay in water supply can mean the difference between saving lives—or losing everything.

Now, imagine your office, factory, or apartment building caught in flames. Would a bucket of water—or even a small extinguisher—be enough? Certainly not. In such situations, a fire hydrant system stands as the backbone of fire safety, providing immediate, high-pressure water access to firefighters.

This guide takes you through everything you need to know about fire hydrants—from how they work to their critical components, global standards, and why no commercial or industrial property should ever be without one.

What Is a Fire Hydrant System?

A fire hydrant system is a specially designed water network that delivers pressurized water during emergencies. Built into underground pipework and connected to visible hydrant valves, it allows firefighters to connect hoses instantly and direct powerful streams of water toward the fire.

Unlike sprinklers or extinguishers—which serve localized purposes—fire hydrants are designed for large-scale firefighting in urban, industrial, and commercial environments.

👉 In short: A fire hydrant is not just a valve; it’s a lifeline that ensures water reaches the flames at the right time, in the right volume, and at the right pressure.

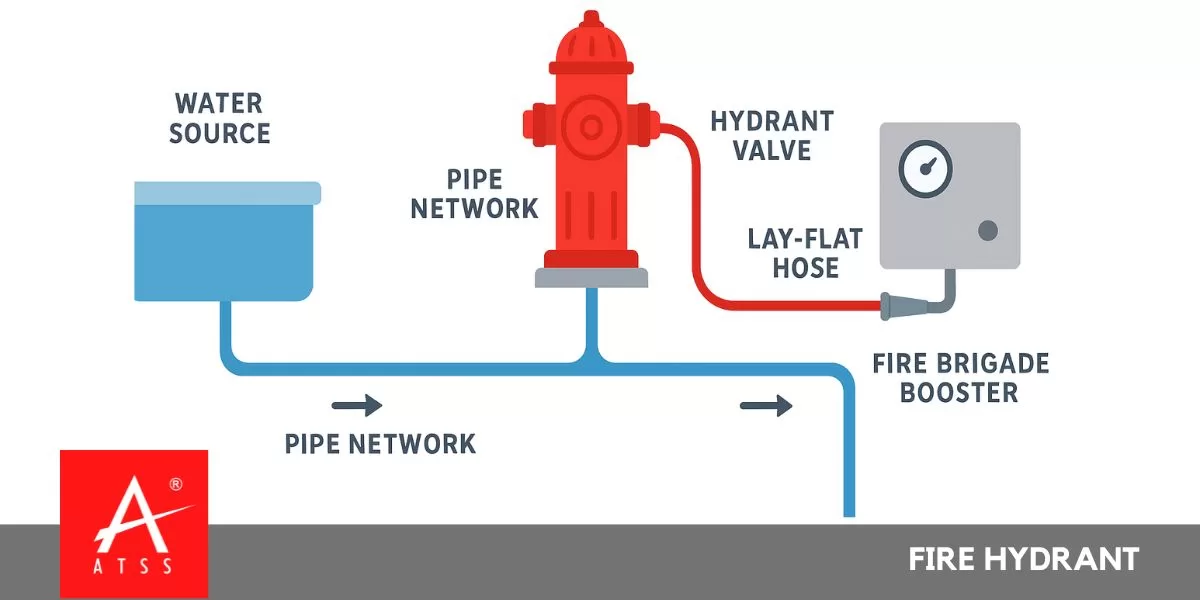

How Does a Fire Hydrant Work?

At its core, the system functions on one simple principle: water under pressure, always ready to fight fire.

Here’s the step-by-step breakdown:

- Water Supply: Connected to a municipal water main, underground storage tank, or reservoir.

- Constant Pressure: Maintained via pipe networks that ensure water is always available.

- Hydrant Valve Operation: Firefighters open hydrant valves and attach hoses.

- High-Pressure Flow: Water gushes through lay-flat hoses and adjustable nozzles.

- Boosters & Pumps: If pressure is low, booster pumps and fire brigade connections provide backup.

- Fire Suppression: Water is directed precisely at the fire’s base until flames are extinguished.

👉 The entire sequence—from alarm to suppression—happens in minutes, ensuring rapid response and minimal damage.

Components of a Fire Hydrant System

For a hydrant system to work seamlessly, every part must be engineered and maintained properly. Let’s break down the essential components:

1. Water Supply and Storage

The foundation of any hydrant system. Without adequate water, the entire network fails.

- Sources: City mains, underground reservoirs, or overhead tanks.

- Requirements:

- Automatic replenishment

- Sufficient volume based on demand analysis

- 24/7 availability

2. Pipework and Valves

The circulatory system of hydrant infrastructure.

- Design Considerations:

- Hydraulic analysis for sizing

- Corrosion-resistant material

- Looping networks for balanced pressure

3. Fire Brigade Booster

The external interface for firefighters.

- Functions:

- Accepts external water from fire trucks

- Boosts pressure without altering internal piping

- Must be located in easily accessible areas

4. Pumpset (Booster Pumps)

Critical for ensuring pressure when the natural supply falls short.

- Features:

- Diesel or electric powered

- Automatic activation when pressure drops

- Backup systems during power failure

5. Hydrant Valve and Couplings

The most visible part—where firefighters connect hoses.

- Specifications:

- Standard 65mm valve size

- Compatible with international fire hoses

- Rugged, corrosion-resistant build

6. Lay-Flat Fire Hose

Flexible, lightweight, and capable of withstanding high pressure.

- Advantages:

- Minimal friction loss

- Easy portability

- Adjustable spray nozzles

7. Block Plan

A map of the hydrant system that guides firefighters.

- Shows hydrant locations, valves, and pipelines

- Indicates capacity and pressure levels

- Must be updated regularly

The Complete Firefighting Process

Here’s how a fire hydrant system comes alive during a real emergency:

- Alarm Triggers – A fire detection system alerts occupants and responders.

- Firefighters Arrive – They quickly locate hydrant points via block plans.

- Connection Setup – Lay-flat hoses are attached to hydrant valves.

- Water Flow – Valves open, water rushes out under immense pressure.

- Pump Support – Booster pumps activate if needed to maintain flow.

- Attack Phase – Water streams are directed precisely to douse flames.

- Sustained Supply – Continuous replenishment keeps water flowing until the fire is under control.

👉 Result: Lives saved, assets protected, and compliance achieved.

Why Fire Hydrant Systems Are Indispensable

✅ Immediate Water Access – A huge supply on standby.

✅ Boosts Firefighter Efficiency – Quick setup, instant attack.

✅ Protects Property & Lives – Reduces spread and damage.

✅ Mandatory Compliance – Required under most building safety laws.

Without hydrants, even the most advanced firefighting unit becomes disabled.

Global Standards for Fire Hydrants

To ensure reliability, hydrant systems must comply with international benchmarks:

- Australia: AS2419 – Fire Hydrant Installation Standards

- USA: NFPA 24 – Installation of Private Fire Service Mains (NFPA Standards)

- India: IS 3844 – Code of Practice for Installation and Maintenance of Fire Hydrants

Compliance ensures uniformity, performance, and global interoperability.

Fire Hydrant System in India

In India, the Bureau of Indian Standards (BIS) mandates hydrant installations for:

- High-rise residential complexes

- Commercial buildings

- Factories and industrial zones

- Public facilities like malls and hospitals

👉 Regular inspections and pressure testing are compulsory for certification.

Fire Hydrant Maintenance and Best Practices

Even the strongest hydrant system becomes useless if neglected. Maintenance is non-negotiable.

Key Practices:

- Weekly Inspections: Check water levels and valve condition.

- Quarterly Testing: Ensure pumps and boosters activate correctly.

- Annual Pressure Tests: Verify hydraulic efficiency.

- Block Plan Updates: Reflect any new changes in piping or hydrant locations.

👉 Remember: A faulty hydrant is as dangerous as having no hydrant at all.

Fire Hydrant Myths vs. Facts

🚫 Myth: Sprinklers are enough for large fires.

✅ Fact: While sprinklers are effective, they only protect localized areas. In contrast, fire hydrants are designed for wide coverage and large-scale suppression.

🚫 Myth: Municipal water supply always provides sufficient pressure.

✅ Fact: This isn’t always true. In many cases, booster pumps are essential to maintain consistent water flow during firefighting operations.

🚫 Myth: Hydrants are only for cities.

✅ Fact: That’s a misconception. Industrial plants, rural facilities, and even airports rely heavily on hydrants for emergency response.

Future of Fire Hydrant Systems

With smart monitoring technologies, the hydrants of tomorrow will be even more powerful:

- IoT-enabled hydrants that send pressure data in real-time

- AI-assisted block plans for faster firefighter response

- Integration with smart city infrastructure

👉 Innovation ensures hydrants remain relevant, reliable, and ready.

Conclusion: Fire Hydrants Save Lives

A fire hydrant system is more than steel pipes and valves—it is the guardian of life and property. When a fire breaks out, this system ensures that brave firefighters are never left powerless.

By investing in a robust hydrant network, you ensure:

- Faster response times

- Better fire control

- Safer communities

🔥 Don’t wait for disaster to strike. Secure your property today with a reliable fire hydrant system.

Call to Action

📞 Want to install or upgrade your fire hydrant system?

👉 Contact us today at 9150012345 for a free consultation and site audit.

Fire Alarm | Smoke Detector | Heat Detector | Multi Sensor Detector | Beam Detector | WhatsApp